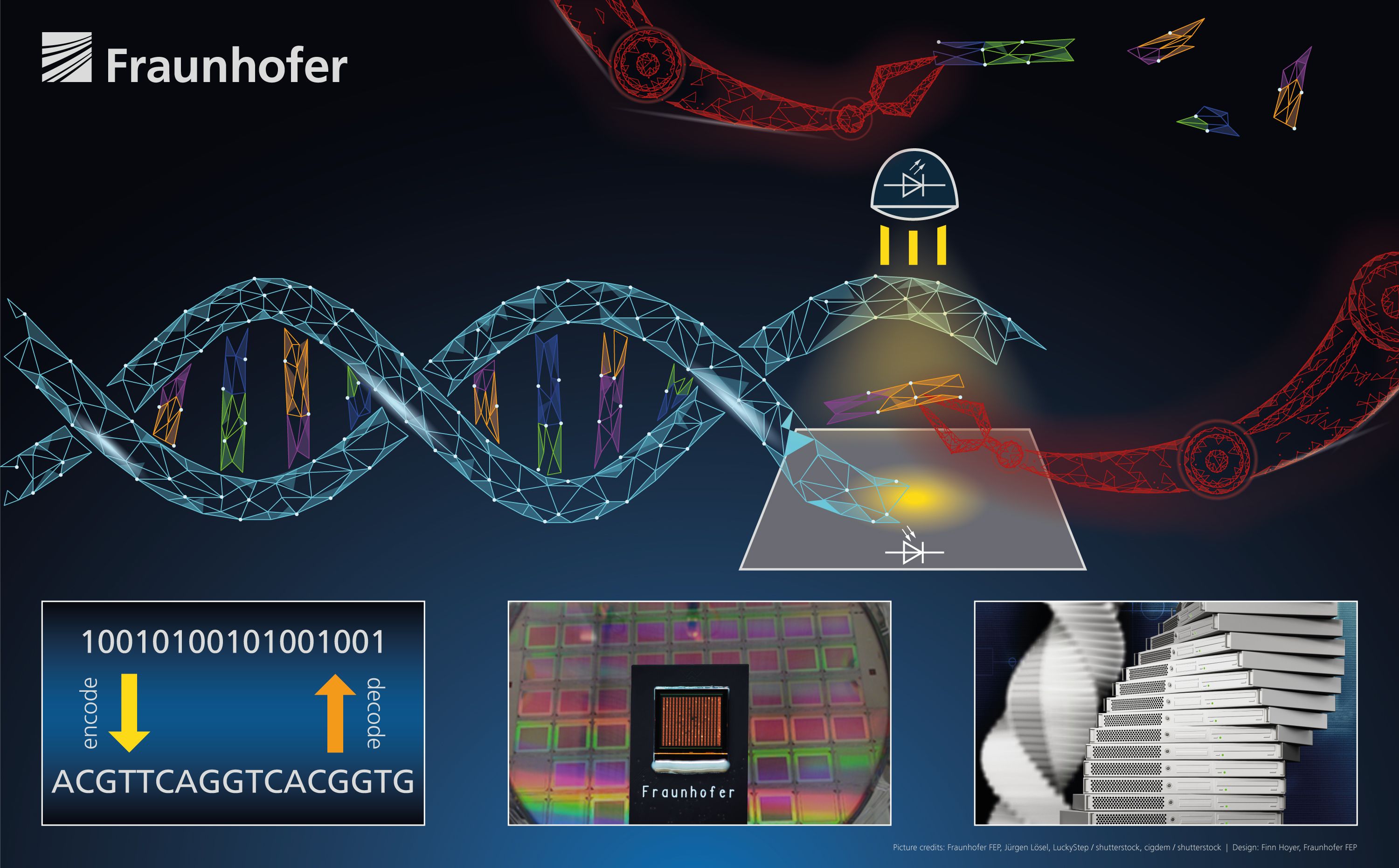

DNA is known as the basic medium for storing genomic information. However, DNA can also be used to store (binary) data – a future technology that has so far been subject of basic research in Europe. This involves transferring microbiological processes from nature to artificial data systems. Writing DNA on microchips is still a big challenge, but also a huge opportunity. For example, information can be stored in very high density directly on a microchip by means of the specific three-dimensional and digitally controllable arrangement of base pairs.

The BIOSYNTH project therefore bundles the know-how of four Fraunhofer institutes with the aim of significantly improving DNA synthesis. This is achieved by means of a universal platform for DNA/RNA/peptide writing. Previous synthesis approaches (including ink-jet) are little efficient in generating long DNA segments. Moreover, they generate numerous inaccuracies, which are time-consuming and expensive to correct. In addition, the corresponding equipment technology is large and cost-intense.

“The BIOSYNTH project therefore aims to lay the technological, biological and information technology fundamentals for biological mass data storage with extremely high storage density and aging resistance,” explains Dr. Uwe Vogel, consortium leader from Fraunhofer FEP.

For this purpose, the project will present a platform based on conventional microchip fabrication technologies for writing software-defined nucleotide sequences (DNA, RNA or peptides). This will then enable the highly parallel and high-rate production of mass data storage devices by reproduction in the volume production processes of the microelectronics industry in the future. In a microplatform designed and manufactured using microelectronics methods, micrometer-level miniaturized reaction cells with picoliter-scale reaction volumes for cell-free synthesis will be integrated into a freely programmable active matrix array assembly. Transport, immobilization, activation and monitoring of process conditions and results will be carried out by means of suitable thermal and photonic components as well as surface functionalization per reaction cell.

Fraunhofer FEP is designing the integrated circuit of the CMOS backplane to control and read out the micro-heaters for biosynthesis, the OLED and photodetector pixels in the active matrix assembly and a corresponding test setup. The task of Fraunhofer IPMS is to develop the “thermo”-layer for the microchip platform. The heating function for adjusting the temperature for biological synthesis is realized by means of structures in surface micromechanics based on the technology of capacitive micromachined ultrasonic transducers (CMUT). In addition, Fraunhofer IMPS is contributing simulation expertise for the thermal functionality. The task within the project will be to implement a MEMS technology that will allow the integration of organic components (organic light-emitting and photodiodes) from Fraunhofer FEP to stimulate and monitor the synthesis process.

Subsequently, colleagues at Fraunhofer IZI-BB in Potsdam will implement the synthesis process using the microchip platform. Fraunhofer ITEM is working on the corresponding coding processes in biological components.

The project is being accompanied by a group of renowned consultants from industry, science and users as well as experts from the University of Marburg, X-FAB, Infineon, the German Federal Archives and Hybrotec. First results will be presented to the public in a user workshop at the end of 2023.

Fraunhofer Institute for Toxicology and Experimental Medicine

Fraunhofer Institute for Toxicology and Experimental Medicine