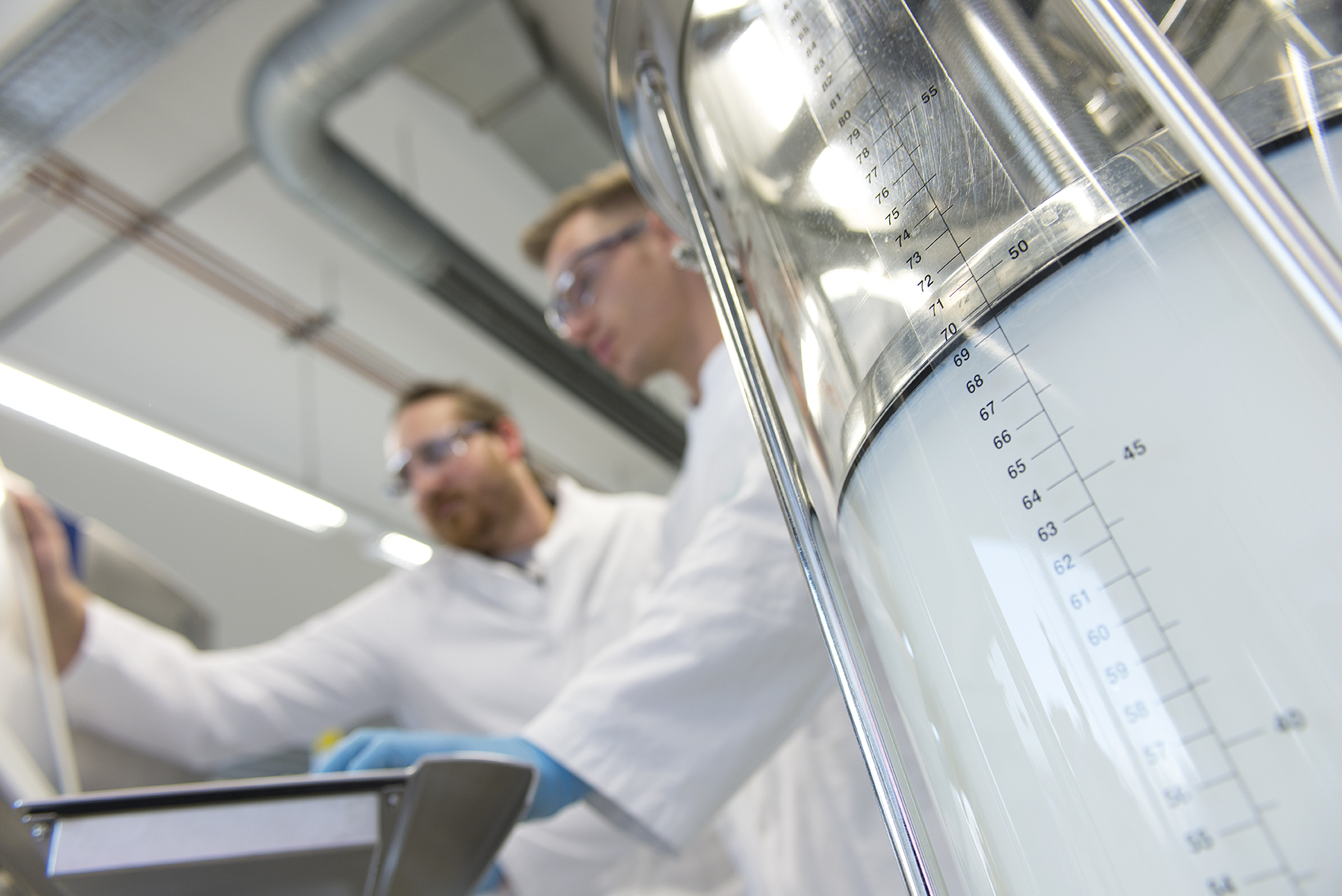

Developing your idea into a sterile IMP in a seamless process

Fraunhofer ITEM has more than 25 years of experience in bioprocess development and in GMP manufacturing of biopharmaceutical active ingredients (APIs) and investigational medicinal products (IMPs) for clinical trials. A multidisciplinary team of biologists, chemists, pharmacists, engineers and technicians assists leads you on your way from the idea for a new biotherapeutic via the development of a production cell line to the manufacturing and release of an IMP. Depending on your requirements, our services can cover either the complete process or only individual phases.

- As a Fraunhofer ITEM client, you will benefit from competences and expertise accumulated over years in a broad range of projects on biotherapeutics – from recombinant proteins and glycoproteins to complex multimolecular structures such as viruses and cells.

- We provide you with the API and IMP and will guide you through the regulatory requirements to an approved IMP dossier for your drug candidate.

- We aid you on your way from the idea for a new biotherapeutic via development of a production cell line to GMP manufacturing of the IMP released for use in clinical trials.

Fraunhofer Institute for Toxicology and Experimental Medicine

Fraunhofer Institute for Toxicology and Experimental Medicine