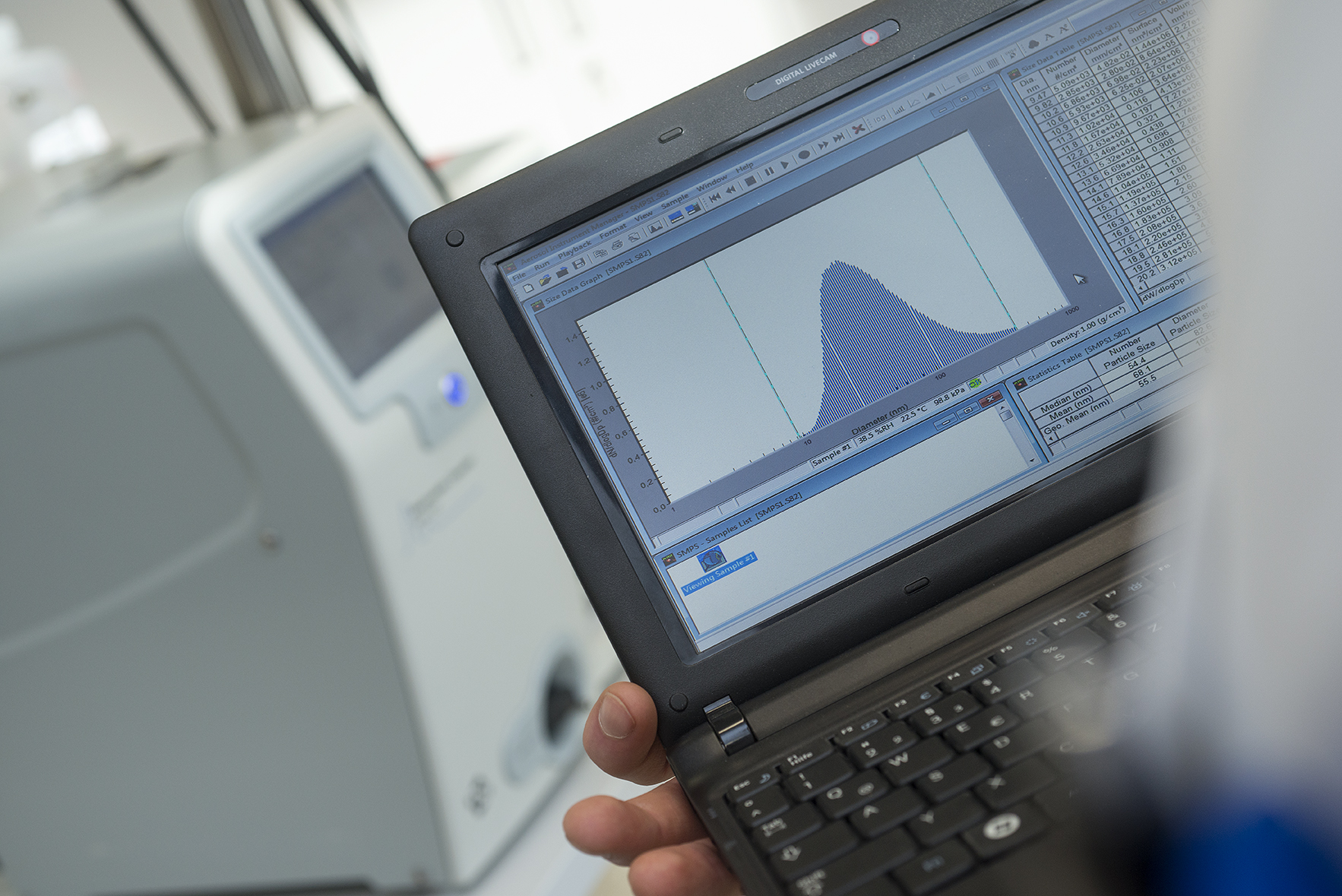

We characterize human exposure to gases and aerosols / particles at workplaces, in indoor air and in the environment, with a focus on inhalation exposure. For this purpose, we combine state-of-the-art measurement technology with mathematical modeling tools and provide necessary adaptations to customize a solution to a client's specific needs or guarantee its compliance with relevant regulations.

Model rooms of various sizes and with adjustable air exchange rates are available for the realistic simulation of aerosol release from spray products and measurement of inhalation exposure, as well as customized measurement technology and methods for analyzing aerosols and gases.

The results serve to assess risks to human health and the environment, to support substance and product registration and authorization, and to improve product safety. The required studies are performed at the Fraunhofer ITEM in compliance with national and international regulations (both GLP and non-GLP).

Fraunhofer Institute for Toxicology and Experimental Medicine

Fraunhofer Institute for Toxicology and Experimental Medicine