The development of production technologies for innovative drugs – ATMPs and biologics – is a research field that has increasingly become a focus at Fraunhofer ITEM. Certain therapeutics, such as CAR-T cells, require personalized manufacturing processes. Development of the necessary production technologies, however, so far has not kept pace with the rapid biomedical progress. Fraunhofer ITEM researchers are seeking to establish scalable and robust technology platforms for the development and manufacturing of biologics. In the future, automated and digitally supported production technologies are to enable rapid, safe, and reliable development of such drugs as well as their production to the high standards of pharmaceutical manufacturing.

For in-vitro diagnostics, Fraunhofer ITEM is further expanding its existing expertise in the fields of single-cell analysis and liquid biopsy. By analyzing RNA and DNA from single cells, the researchers aim to gain additional information from the valuable clinical samples and to derive new therapeutic strategies from this information. The combination of multi-omics and functional data creates novel tailored analysis platforms for this purpose.

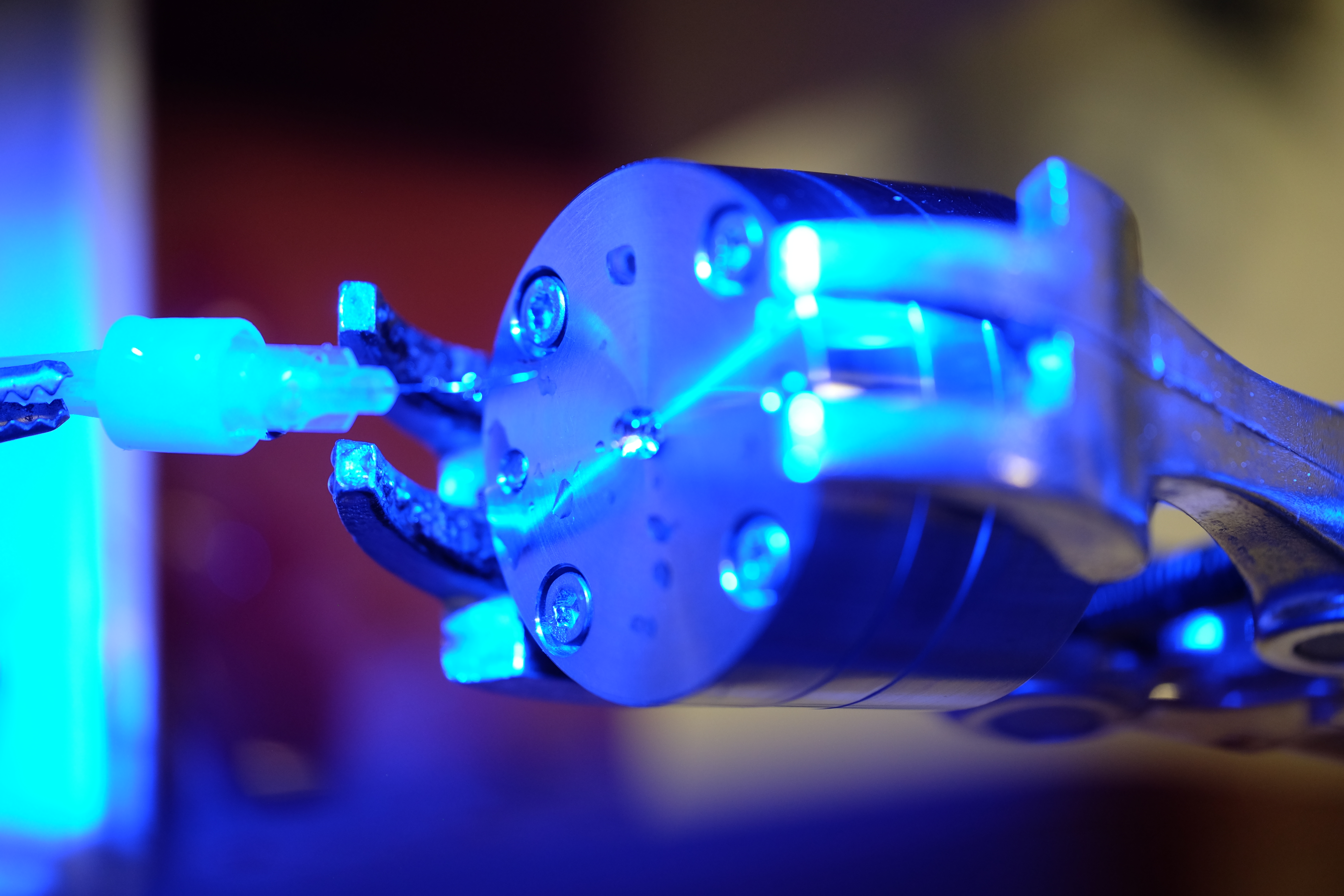

Another field of research establishes test methods that can be used to evaluate the long-term durability of implants. Key topics are the testing of active implants, such as evaluation of the long-term performance of neural implants, and test systems for functional implants, including ones with anti-infective or anti-fibrotic effects. The aim is to foster biomimetic approaches and reduce implant testing in animals. In view of the regulatory requirements for medical devices, it is particularly important to have a regulatory strategy in place as early as possible. The necessary conformity assessment can then be performed smoothly, accelerating time to market for new products. A comprehensive database of requirements and materials for optimized (re)certification of medical devices is being set up.

Fraunhofer Institute for Toxicology and Experimental Medicine

Fraunhofer Institute for Toxicology and Experimental Medicine