Manufacturing of cell banks represents the first GMP element in the life cycle and production chain of a medicinal product. It is a prerequisite for consistent production of a biological API. Since repeated subcultures or multiple generations of organisms can result in unforeseeable changes in properties and integrity, production of every biological drug substance is based on a master cell bank (MCB) and a working cell bank (WCB) prepared with low numbers of generation doublings. A two-tier cell bank system consisting of a MCB and WCB guarantees consistent raw material/cellular substrate supply over the life cycle of a biopharmaceutical drug product and beyond.

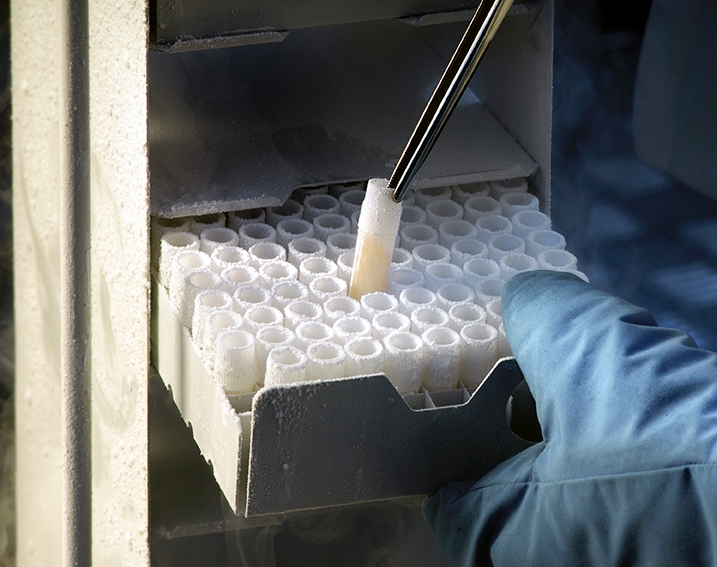

An additional aspect is the storage of cell banks. This should take place in a secure, controlled, and monitored cell bank system at ultra-deep temperatures, i.e. in the gas phase above liquid nitrogen.

Fraunhofer Institute for Toxicology and Experimental Medicine

Fraunhofer Institute for Toxicology and Experimental Medicine