The first manufacturing license for GMP facilities was obtained in 1997. Since then, this license has been extended for a wide variety of biopharmaceutical drug substances, such as recombinant and monoclonal antibodies, epoetins, lymphokines, therapeutic enzymes, and nucleic acids/plasmids.

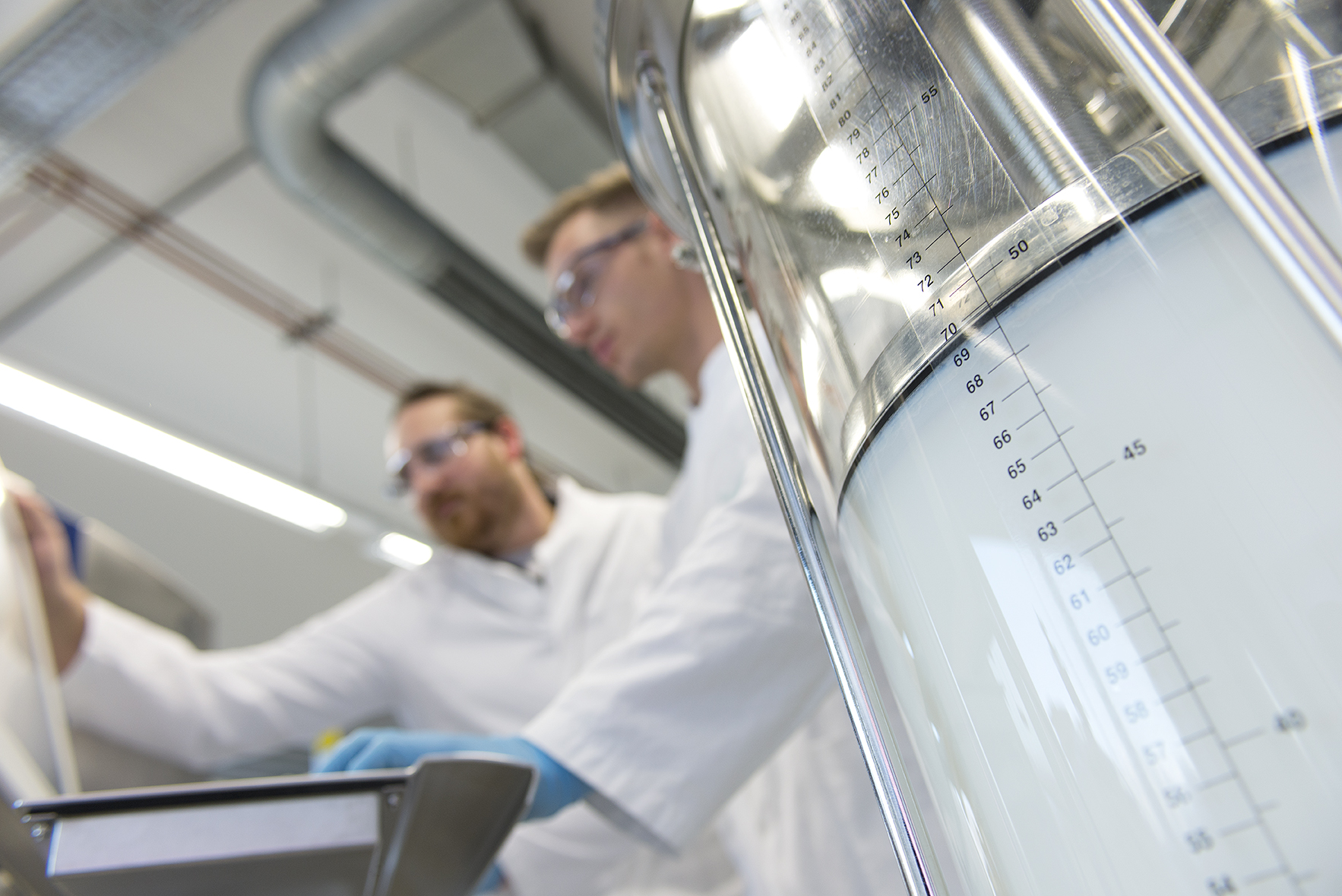

Cultivation of microbial and mammalian cells in volumes up to 400 liters is performed in bioreactors equipped for operation in batch and fed-batch mode. Perfusion mode cultivations are performed with reactor volumes up to 50 liters. Purification hardware consists of commercial process chromatography and membrane filtration systems and enables purification of biomolecules in batch sizes up to 100 grams.

For the manufacture of investigational biopharmaceutical drug substances GMP operations are performed in particle controlled environments (clean rooms). For such operations, Fraunhofer ITEM has a comprehensive 600-m² facility based on grade-B (class 100), grade-C (class 10,000) and grade-D (class 100,000) clean rooms. In grade-C clean rooms, inoculum preparations, open-unit operations, and the final purification steps are performed. Grade-D clean rooms serve to carry out final seed train steps, bioreactor harvesting, and initial purification steps.

Fraunhofer Institute for Toxicology and Experimental Medicine

Fraunhofer Institute for Toxicology and Experimental Medicine